Description

The BC1000E by VTM is an electric-powered brush chipper designed for stationary applications and for users in the biofuel and waste reduction industry who demand an organic waste reduction option that helps minimize fuel emission issues.

The heavy-duty, all-steel motor enclosure is designed to hold up to daily use and wear. The unit’s large feed opening enables you to process material up to 11.8 in (30 cm) in diameter, which maximizes productivity by minimizing the need to trim material.

| Feature | Benefit |

| 45 kW Per Hour (60.3 hp) Electrical Consumption | |

| The Siemens electric motors use 45 kW (60.3 hp) per hour of electricity under normal operating conditions. | Lower operating costs then diesel or gasoline-powered engines, plus zero carbon emissions are produced by the electric motors. |

| Bottom Feed Stop Bar | |

| The bottom reed stop bar is strategically located to make it possible for an operator’s leg to strike the bar and shut off the feed mechanism either intentionally or automatically in an emergency situation. Reset/hold to run buttons on each side of the infeed housing allow the operator to readily reset the system if the bar is tripped. | Enhances operator safety while feeding material. |

| Control Panel | |

| The control panel is located on the rear of the unit beside the infeed. | This allows the operator easier access to the necessary control switches while the machine is in operation. |

| Four-Position Feed Control Bar | |

| This design allows the operator to easily control feed direction and provides an additional way to stop the infeed, enhancing operator safety. | A four-position feed control bar is positioned within easy reach of the infeed housing and allows the operator to control the forward or reverse direction of the feed roller. In addition, the operator can push or pull the feed control bar, stopping the feed roller. |

| Large Infeed Opening | |

| The BC1000E brush chipper by VTM features a 30 cm (11.8 in) tall and 43 cm (16.9 in) wide infeed opening. | This design can help boost productivity by decreasing the amount of trim cuts needed prior to processing. |

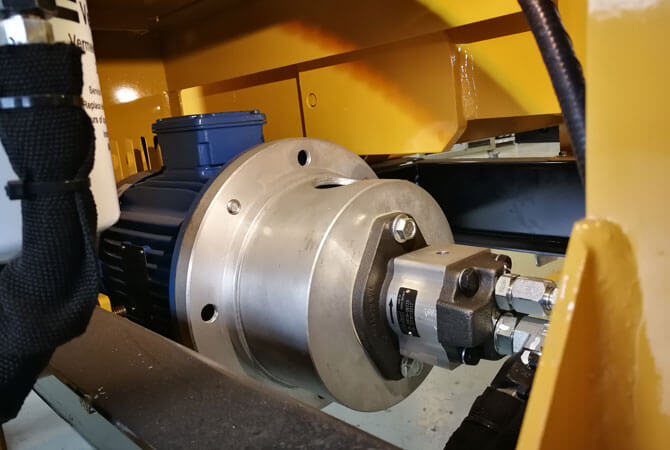

| Motor enclosure and Dust- and Weather-Proof Electric Motors | |

| All-steel motor enclosure and IP55 rating for the motors. | The heavy-duty enclosure is designed to hold up to the daily use and wear, with motors protected from dust and weather conditions. |

| SmartFeed | |

| SmartFeed is a patented feed-sensing control system which monitors motor current and automatically stops or reverses the feed roller. | This exclusive system from Vermeer helps increase operator productivity and reduces strain on vital motor parts. |