Description

As the need for more infrastructure and utility installation grows, you can efficiently tackle fiber, electrical, gas, water, and other projects with the D60SG2. Manufactured in Tianjin, China, with the high-quality parts and components that Vermeer is known for, this drill is built tough for your jobsite conditions and high-quality performance.

Our commitment is to help you tackle jobs in tight spaces and challenging soil types. This new generation of D60SG2 drills can handle a variety of applications and jobsites to help maximize productivity and connect you to the world. It’s equipped with features that promote ease of operation and powerful torque and thrust to keep you drilling quickly and efficiently.

| Feature | Benefit |

| Plus+1 control system | |

| The control system in the D60S has been upgraded to Plus+1 software in comparison to the generation 1 model. | Paired with the AutoSteer system, which automates certain drill head motions, you can set and adjust rotation duration and direction while maintaining a preset thrust pressure to get through hard ground conditions, enabling drilling consistency. |

| Powerful torque and thrust | |

| With an overall increase in power and torque, the D60S is one of the most powerful drills in its class. | It has up to 60,000 lb (266.9 kN) of thrust and pullback and 9,000 ft-lb (12,202.4 Nm) of rotational torque, allowing operators to maximize their efficiency and productivity. |

| Impressive footprint | |

| The D60S comes with a standard remote control for ease of use that helps you efficiently load and unload the drill. | A modest footprint of just 100-in (254-cm) transport width and 26-ft (7.9-m) length allows the D60S to fit a range of installation specifications—even congested urban jobsites. |

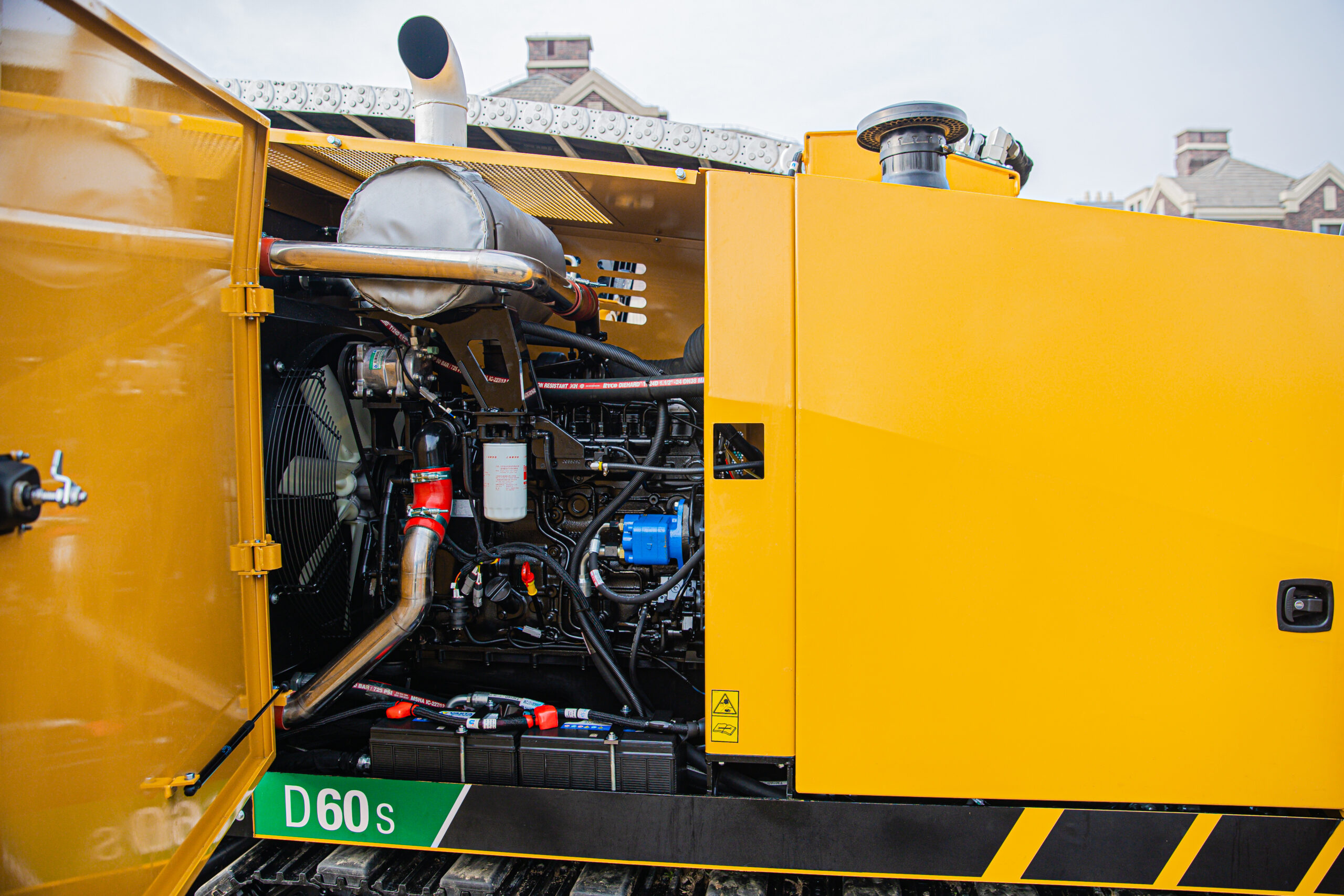

| Ease of serviceability | |

| The D60S engine hood can pivot and is only one piece. | This design provides convenient access to internal components for ease of serviceability and maintenance checks. |

| Three-speed gearbox | |

| The three-speed gearbox helps improve overall drilling efficiency. | This system allows the operator to adjust the machine’s rotational torque to match different ground conditions. |

| Operator-controlled rod loader | |

| This feature helps reduce the labor involved with manually loading and unloading drill rod. | The operator-controlled rod loader provide better overall drilling efficiency. With an added rod function, single rods can be loaded quickly instead of changing the rod box. |